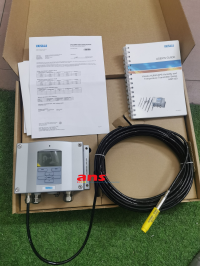

OmniLab® automated sampling system, AGR Vietnam

Xuất sứ: MỸ

Nhà cung cấp: AGR VIETNAM

Hãng sản xuất: AGR VIETNAM

♦ Dương Huỳnh Thảo My ♦

Sales Engineer ANS Vietnam

PHONE “+84 938.140.396”

IE-mailI my.duong@ansgroup.asia

ISkypeI my.duong@ansgroup.asia

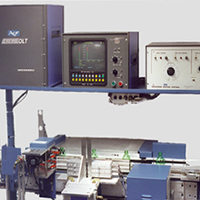

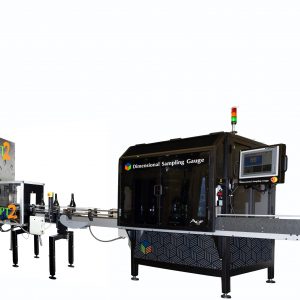

The OmniLab® system incorporates two powerful Agr sampling and measurement devices, the Dimensional Sampling Gauge 400 and the Sampling Pressure Tester 2, into one totally integrated testing station that can communicate with plant wide process control systems. The OmniLab system can be configured to operate as a stand-alone testing station, where operators can load the station with up to 48 containers for hands-free testing, or interconnected with the production system to receive bottles automatically from upstream selection devices.

One system to manage multiple measurements and inspections

- Dimensional measurements

- Finish gauging

- Bore/ID profiling

- Pushup

- Weight

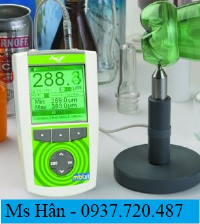

- Thickness

- Pressure testing

- Volume Fill/Height Measurement

All data is mold correlated and presented in a single consolidated report

Features

- Automated sampling and testing

- Single User interface for all testing and reporting

- Compatible with popular process control systems

- Capture, display and correlation of data from multiple devices, in one location

- Hands-free sample management

- Multiple line support

- Interconnect conveyors

Key OmniLab Components

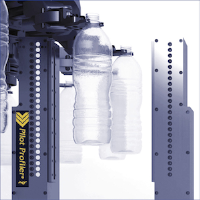

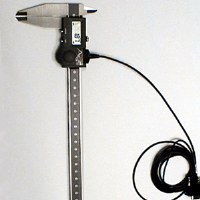

Dimensional Sampling Gauge 400

The Dimensional Sampling Gauge 400 (DSG400) provides comprehensive dimensional weight and thickness measurement capabilities with fast hands-free operation

Proven over time, the Agr SPT2 provides pressure testing and volume of sampled products with high accuracy and unmatched reliability

The Thickness 360™ Gauge brings comprehensive, high-accuracy thickness measurement capabilities to the DSG400.